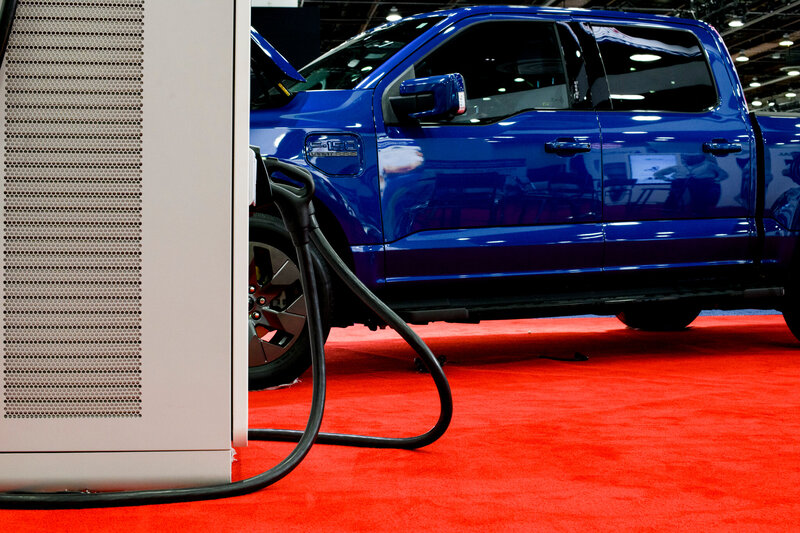

On Tuesday, Ford Motor said that, in part due to the poor uptake of electric vehicles in the country, it was starting construction on a new battery facility for electric vehicles in Michigan but drastically reducing its ambitions.

A representative for the business said that while manufacturing was still scheduled to start in 2026, Ford now anticipated that the Marshall, Michigan factory would generate 1,700 employment as opposed to 2,500.

According to T.R. Reid, a Ford spokesperson, the demand for electric cars is “not growing at the rate that we originally expected.” Large automakers like Ford said in the most recent quarter that electric vehicle sales had improved, but not quickly enough to meet the aggressive targets set by the Biden administration.

Originally, Ford predicted that the factory could manufacture 35 gigawatt-hours of batteries yearly, which would have been sufficient to power around 400,000 cars. From now on, the plant will generate 20 gigawatt hours per year, or 42.8 percent less, than needed to power around 230,000 cars.

Ford said that the money it would be withdrawing from the project would be about equal to the production cut, although it did not say how much specifically. Applying the 42.8 percent production decrease to its investment would mean a $1.5 billion drop from the $3.5 billion that was first promised.

Ford said in September that it was pausing construction due to worries that it would not be able to produce goods at a cost that would be competitive. The United Automobile Workers union and the firm were engaged in heated talks at the time.

According to Mr. Reid, Ford’s decision to reduce its plans for the production was partly influenced by growing labor expenses. The top compensation for manufacturing workers will increase by 25% as a result of Ford and the UAW’s approved contract deal.

Under the deal, UAW members will be able to be relocated to battery and electric car factories that are currently under development, such as the Marshall factory. Employees there are covered by the UAW contract if they decide to form a union.

In the midst of the shift to electric cars, the UAW seeks to maintain a high membership rate; however, the automakers have resisted, claiming that it disadvantages them in comparison to their nonunionized rivals.

When asked for comment on Tuesday, the U.A.W. did not answer right away.

Conservative MPs have also criticized Ford for its intention to license technology from Chinese battery manufacturer CATL. The United States does not presently make lithium-iron-phosphate (LFP) batteries. Certain American electric vehicle manufacturers, including Tesla, purchase LFP batteries from China.

It’s unclear whether American businesses that license technology from other nations will be able to take advantage of government incentives to encourage the transition away from fossil fuels. Ford was “confident about the technology licensing agreement for this plant,” according to Mr. Reid.

+ There are no comments

Add yours